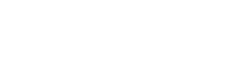

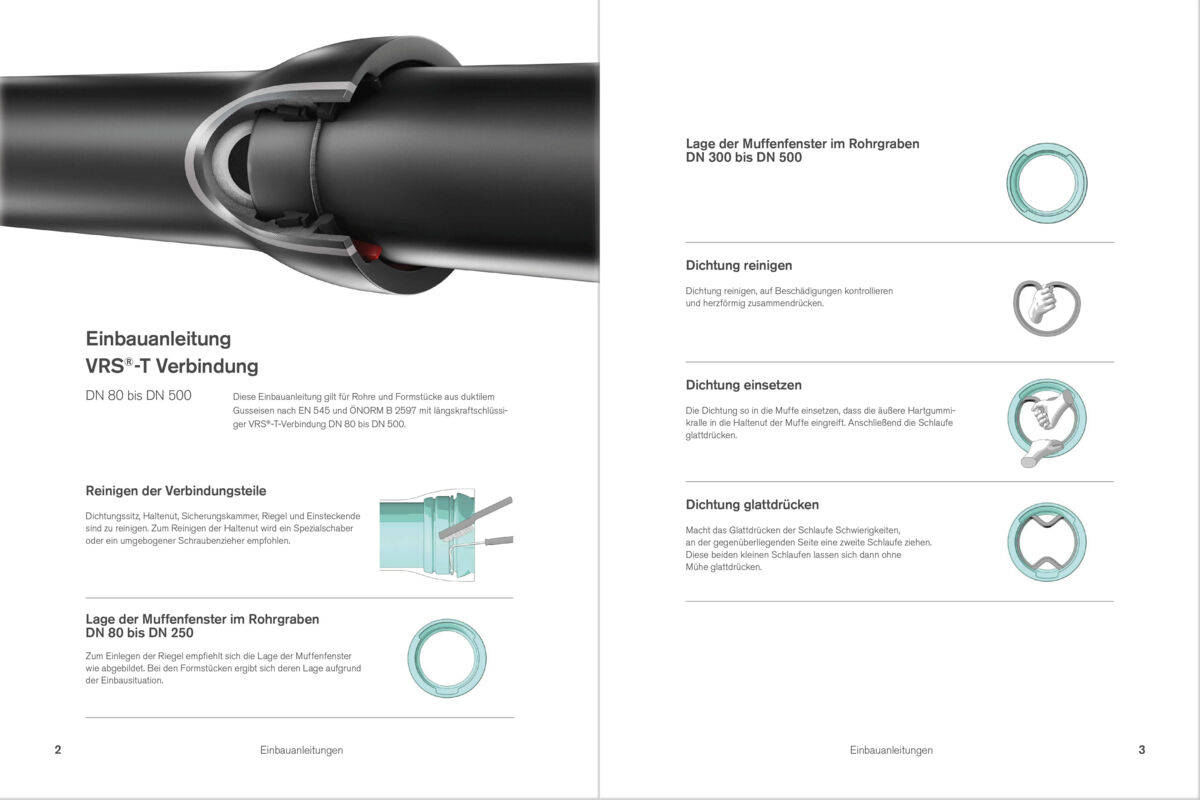

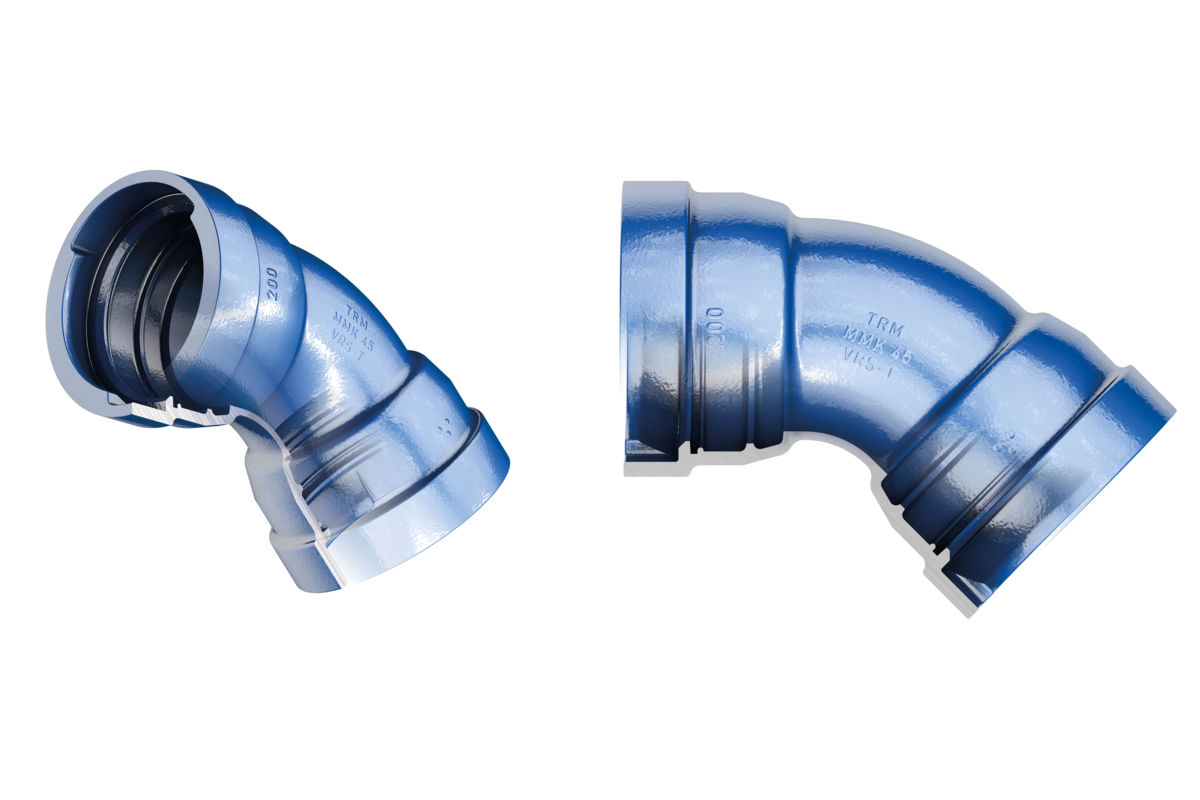

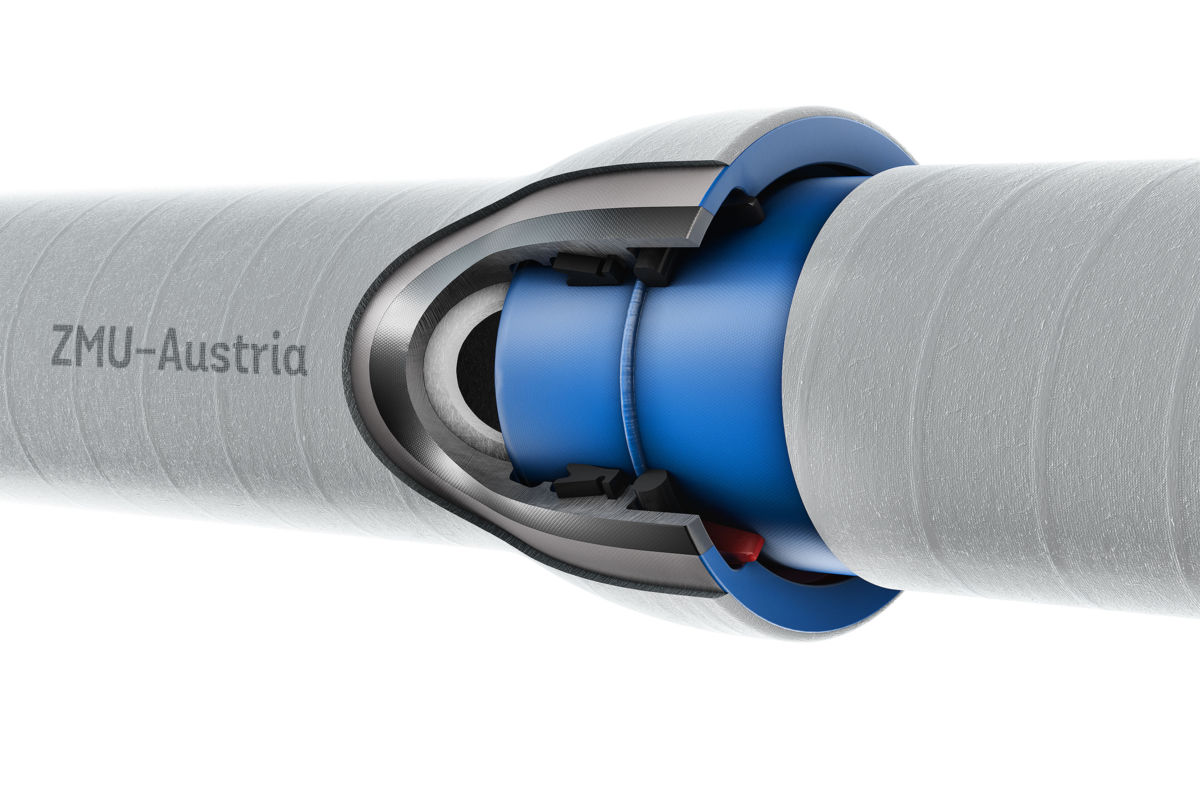

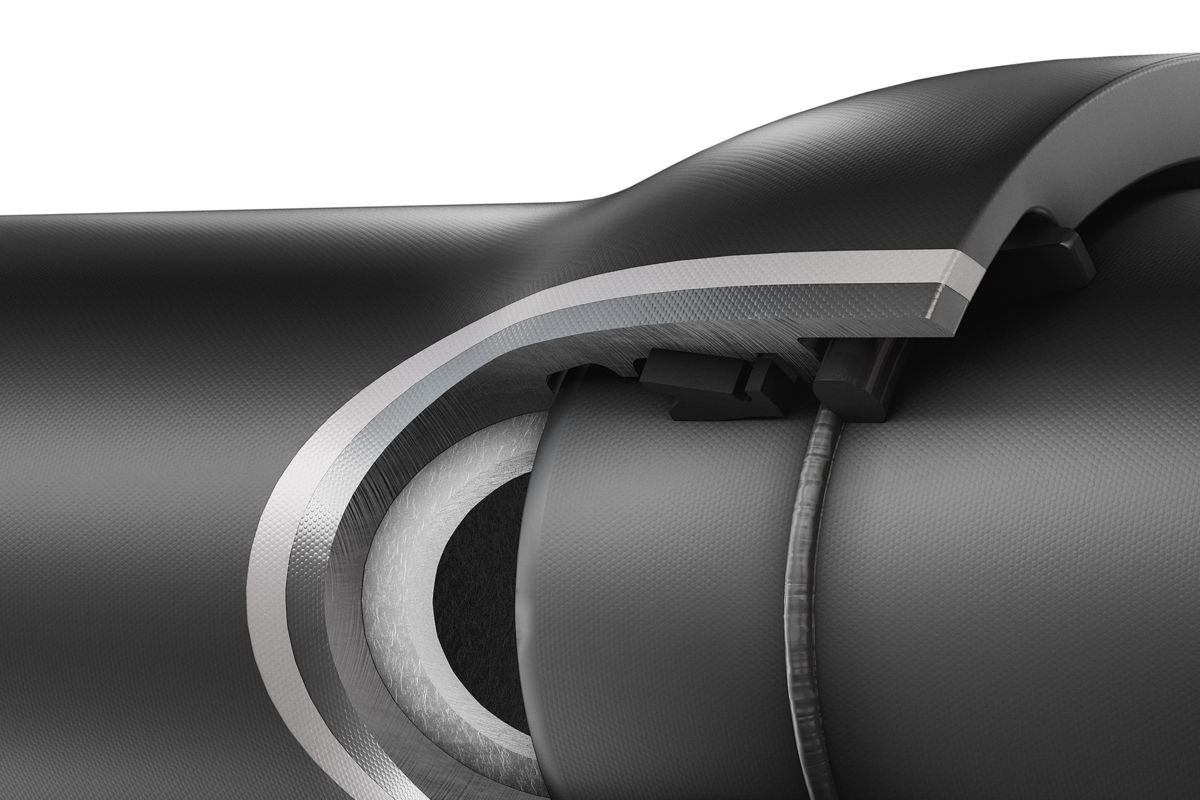

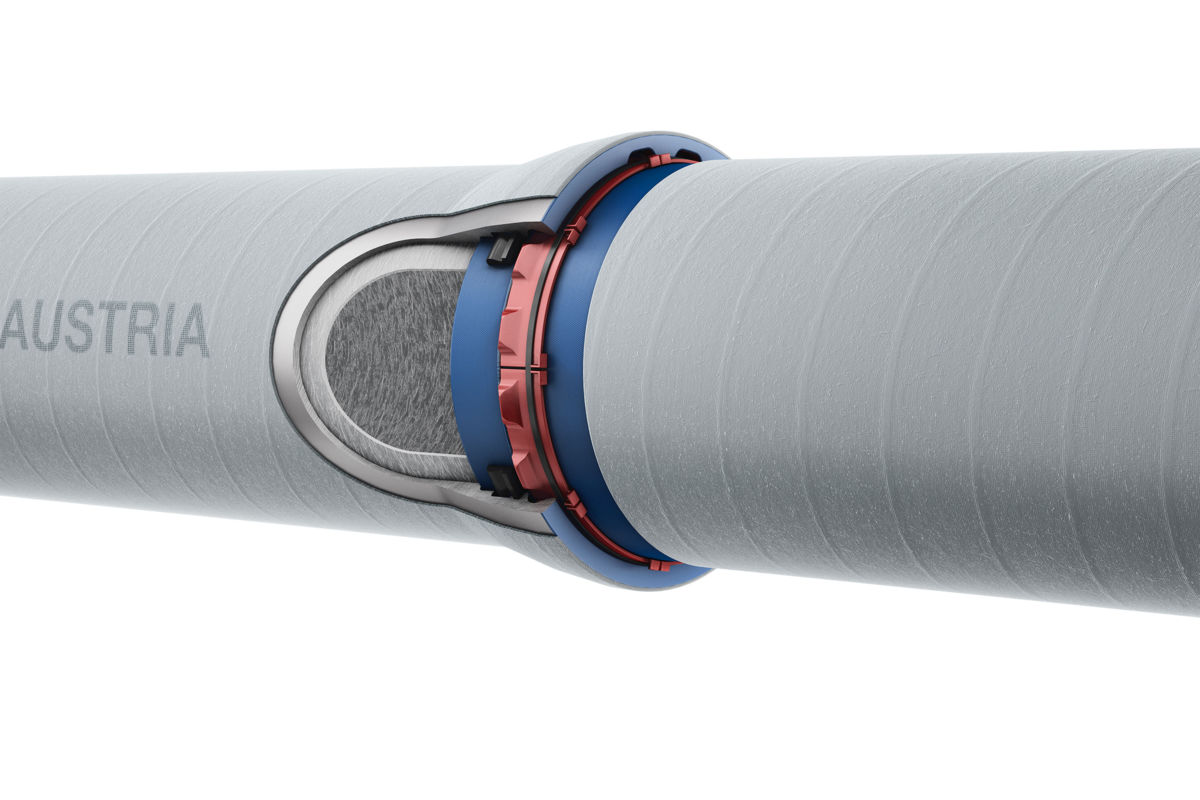

Restrained VRS-T connection

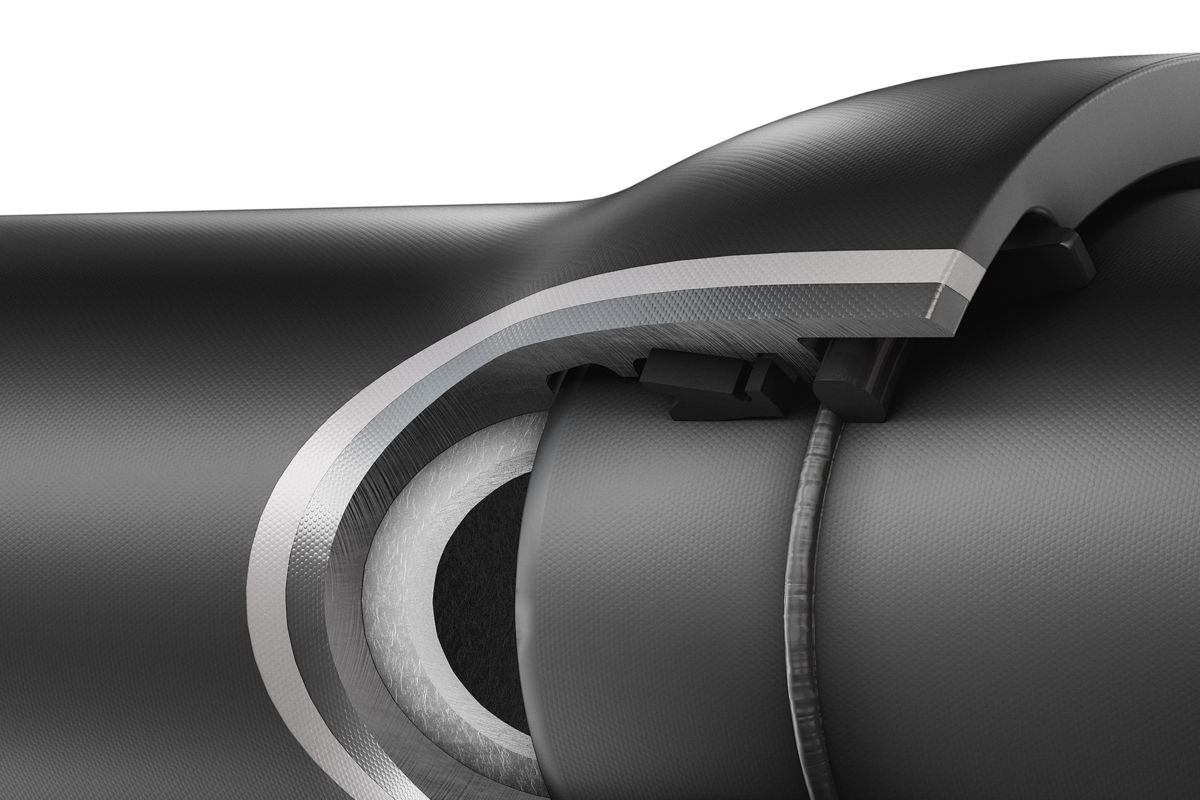

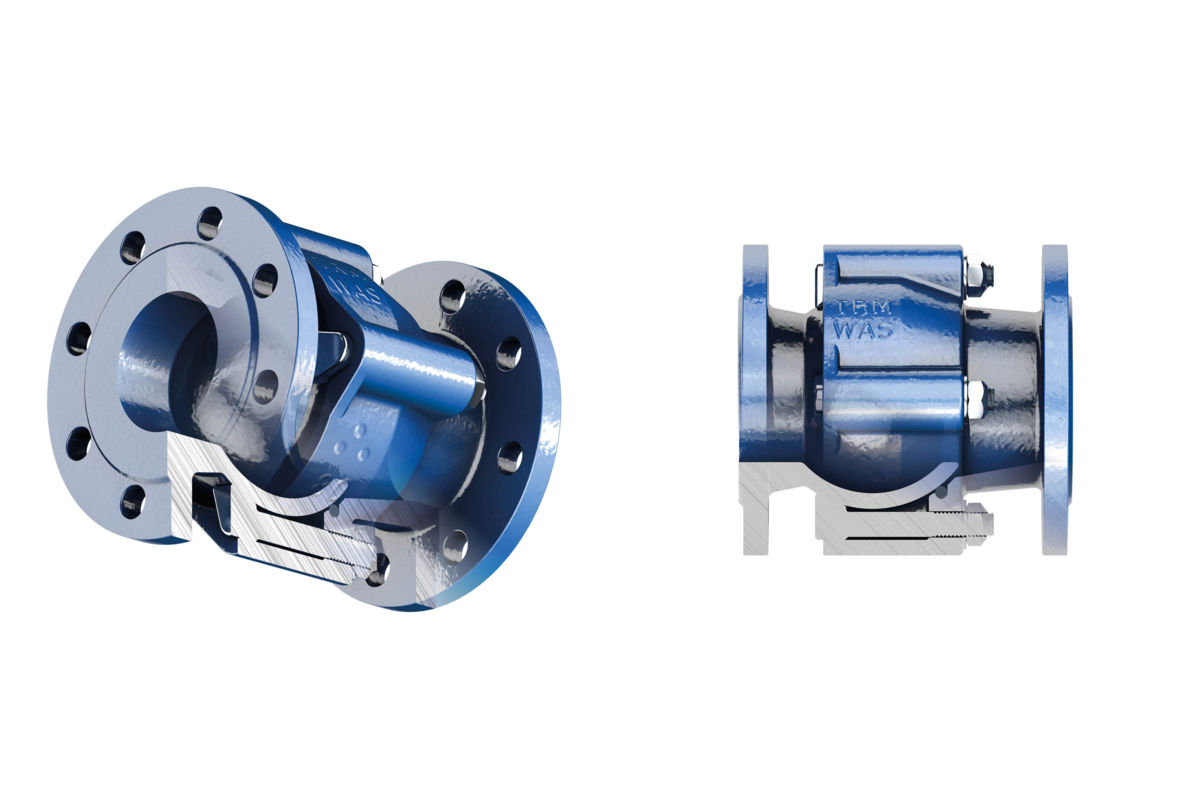

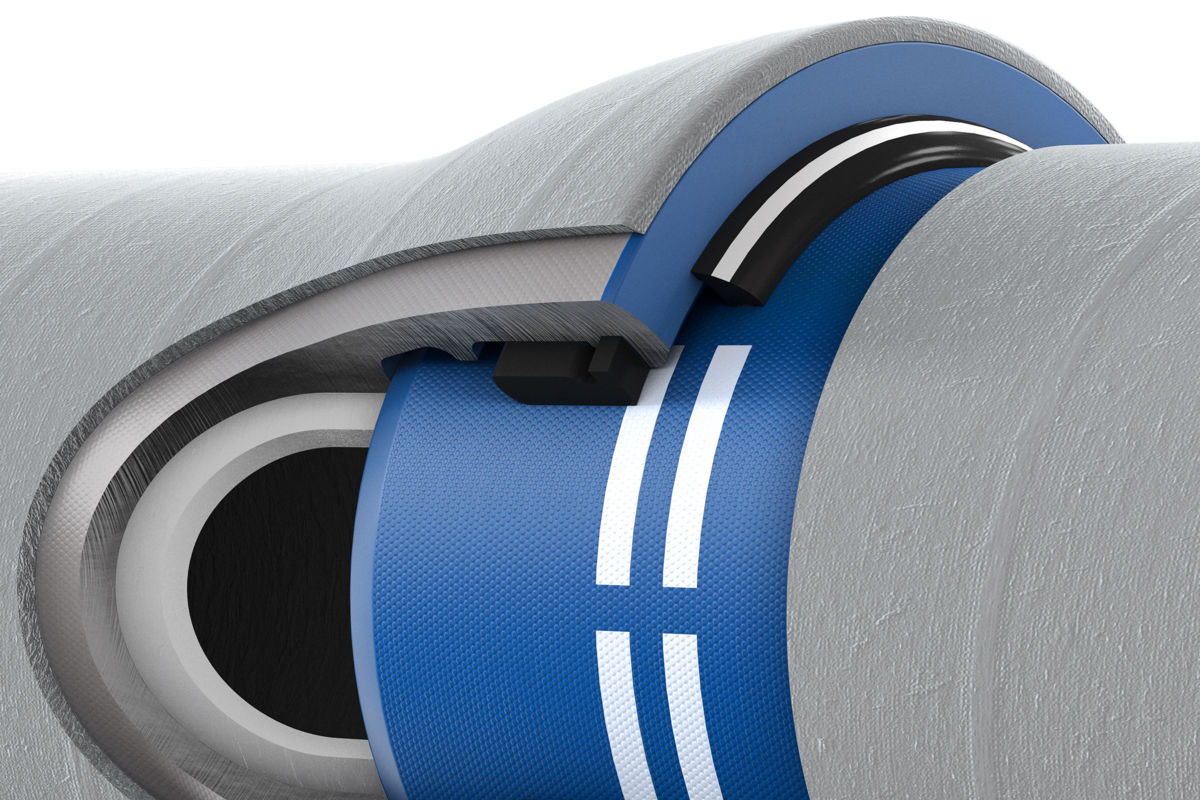

Non restrained TYTON connection

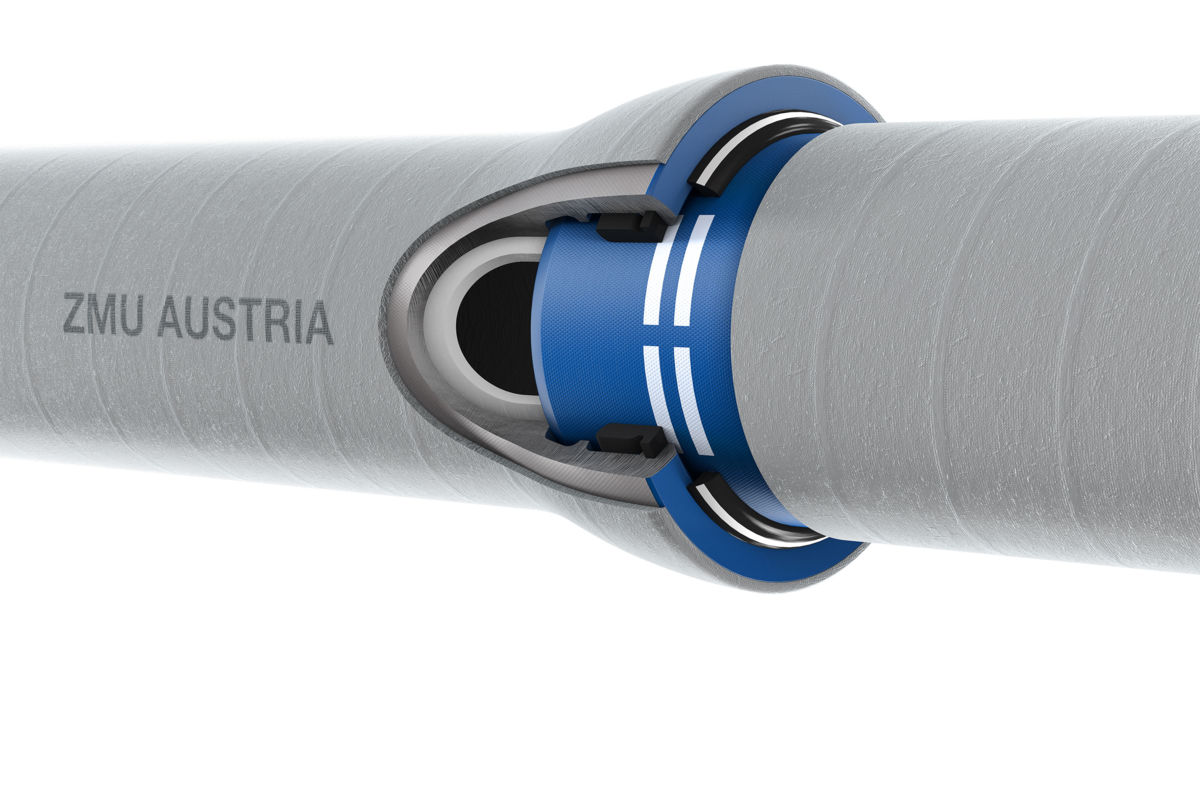

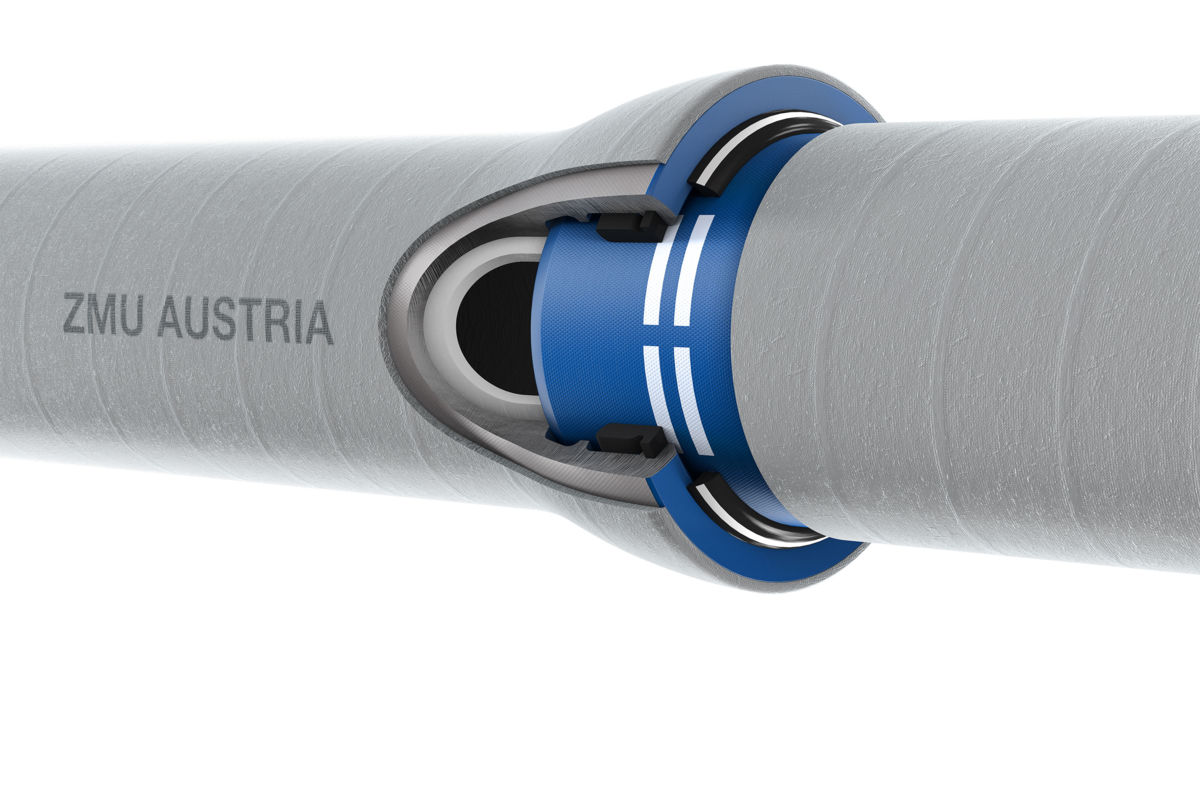

Restrained BRS Connection

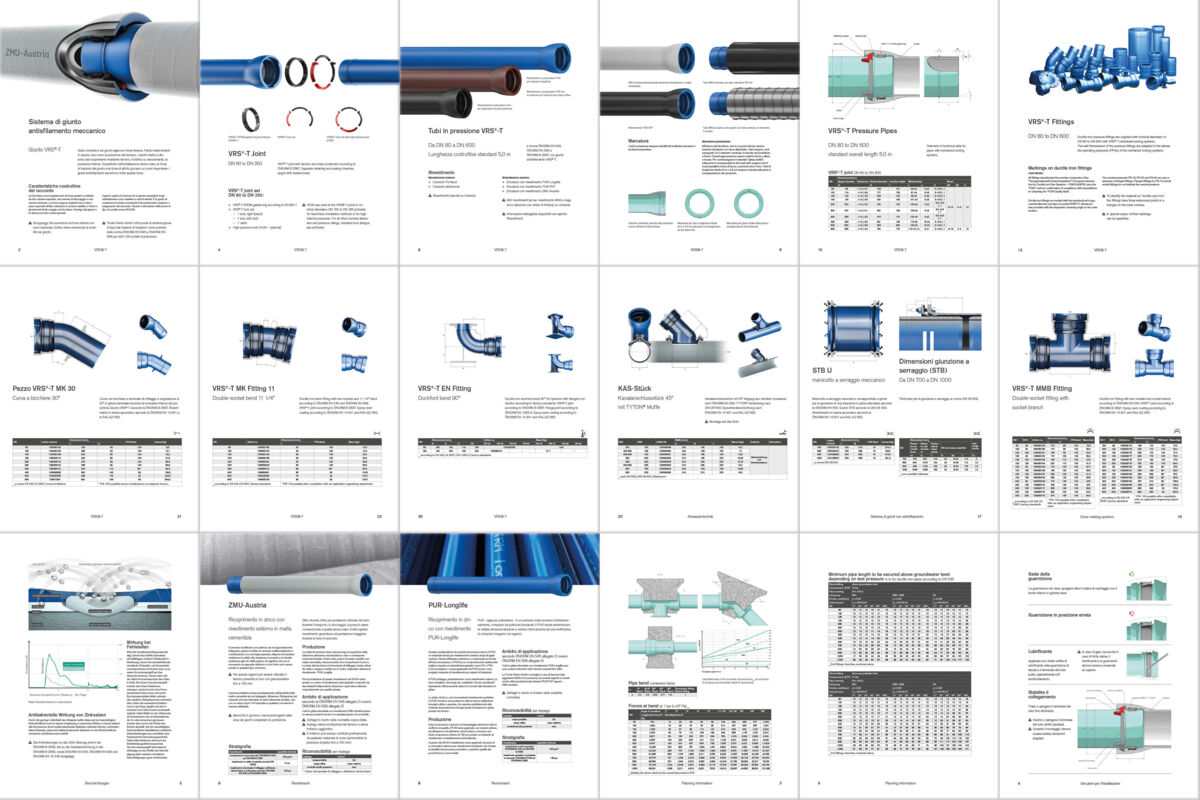

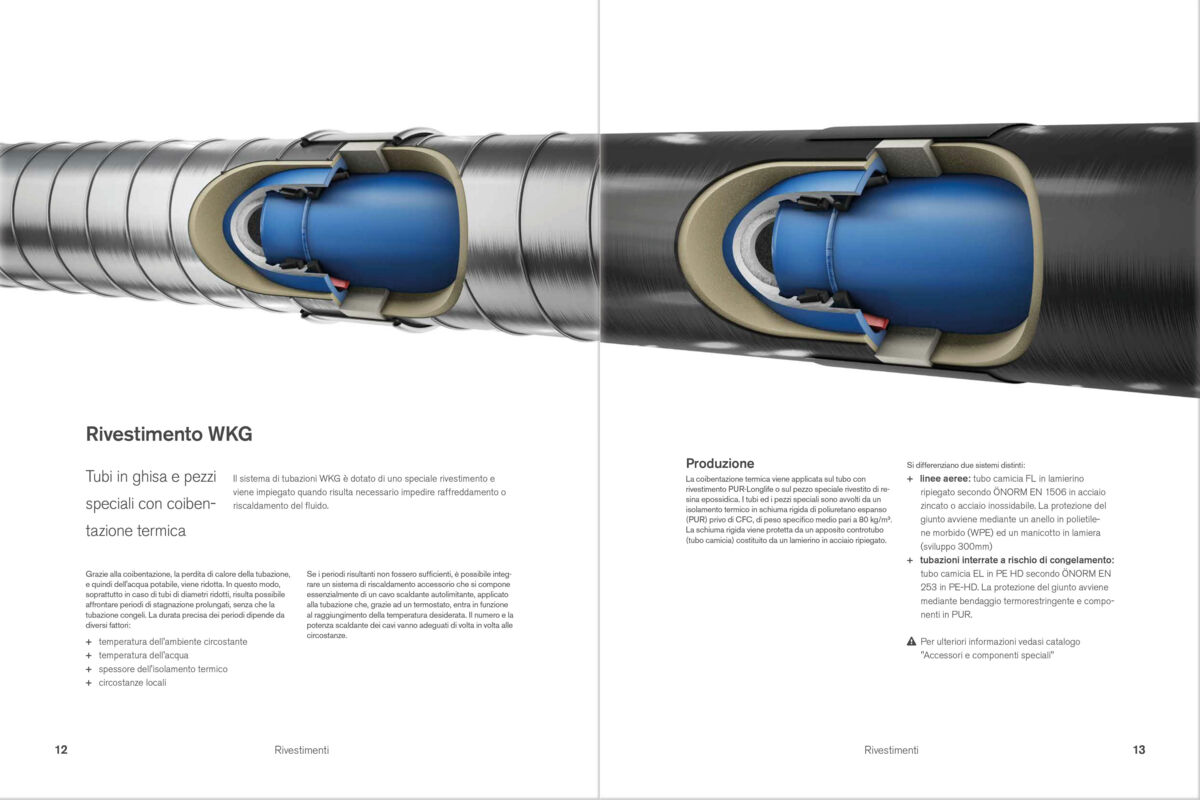

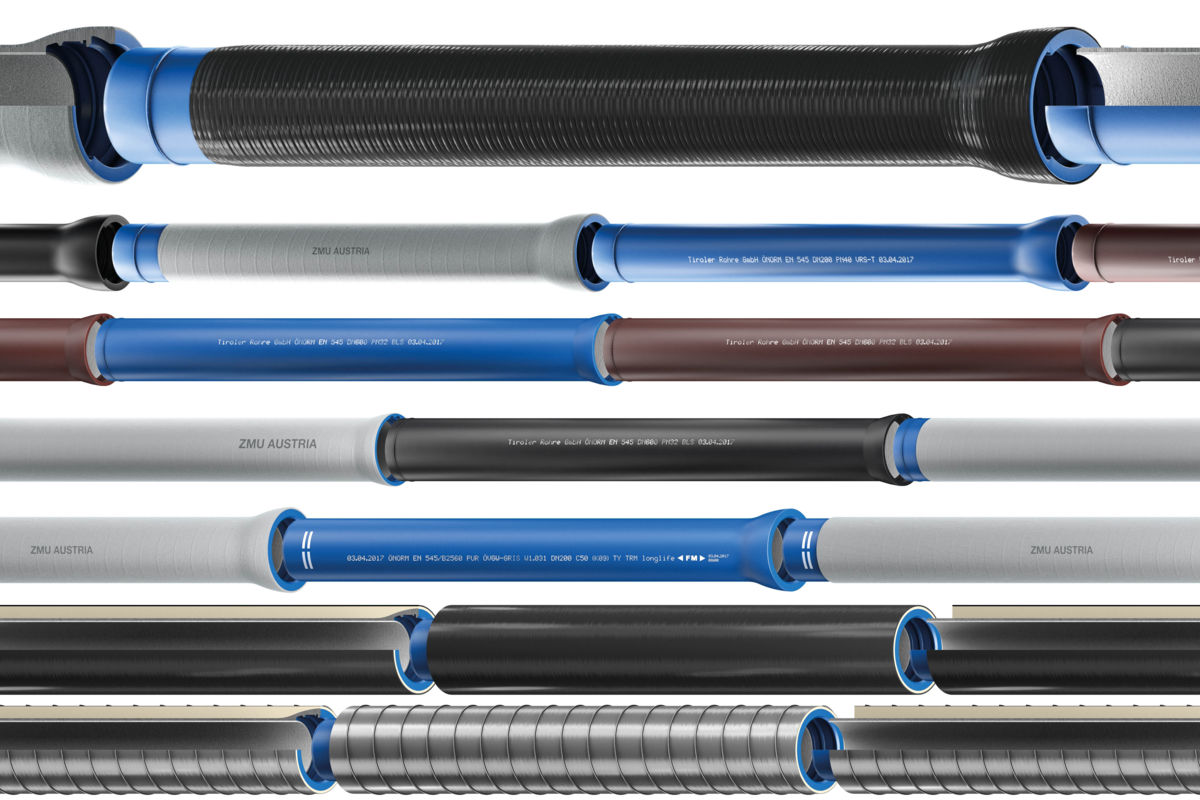

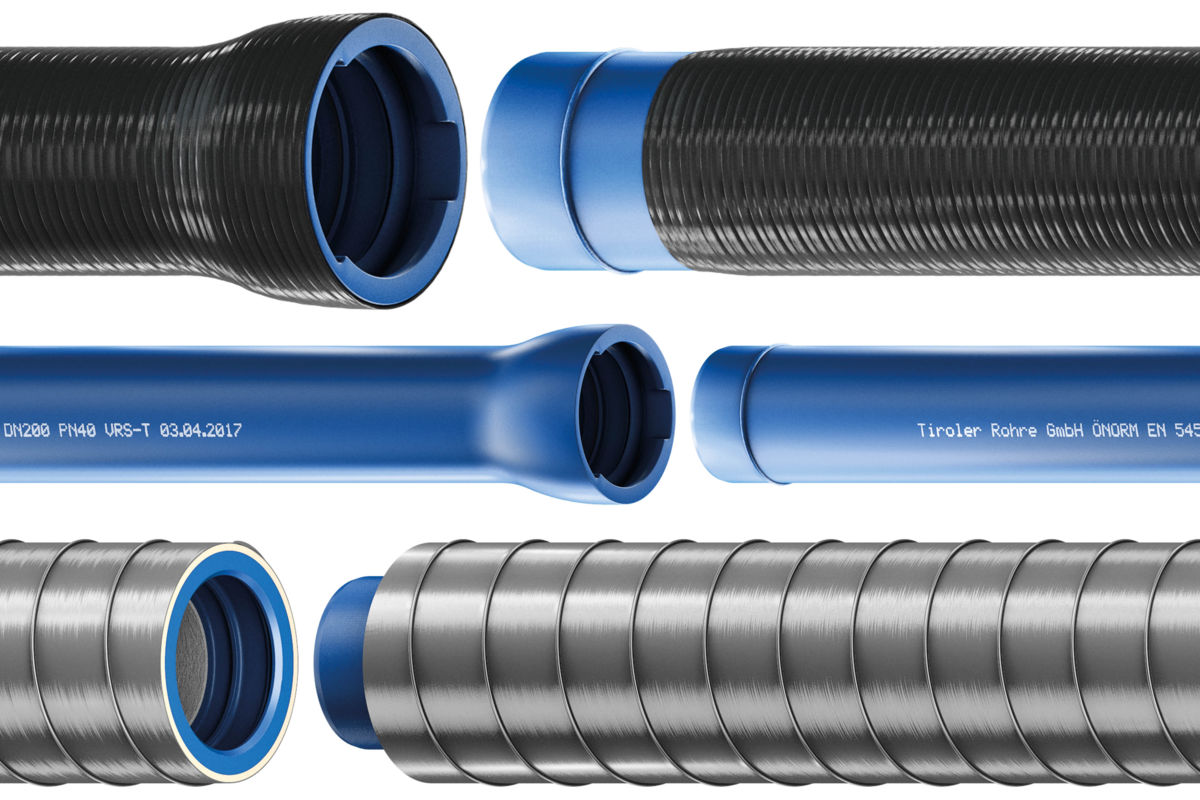

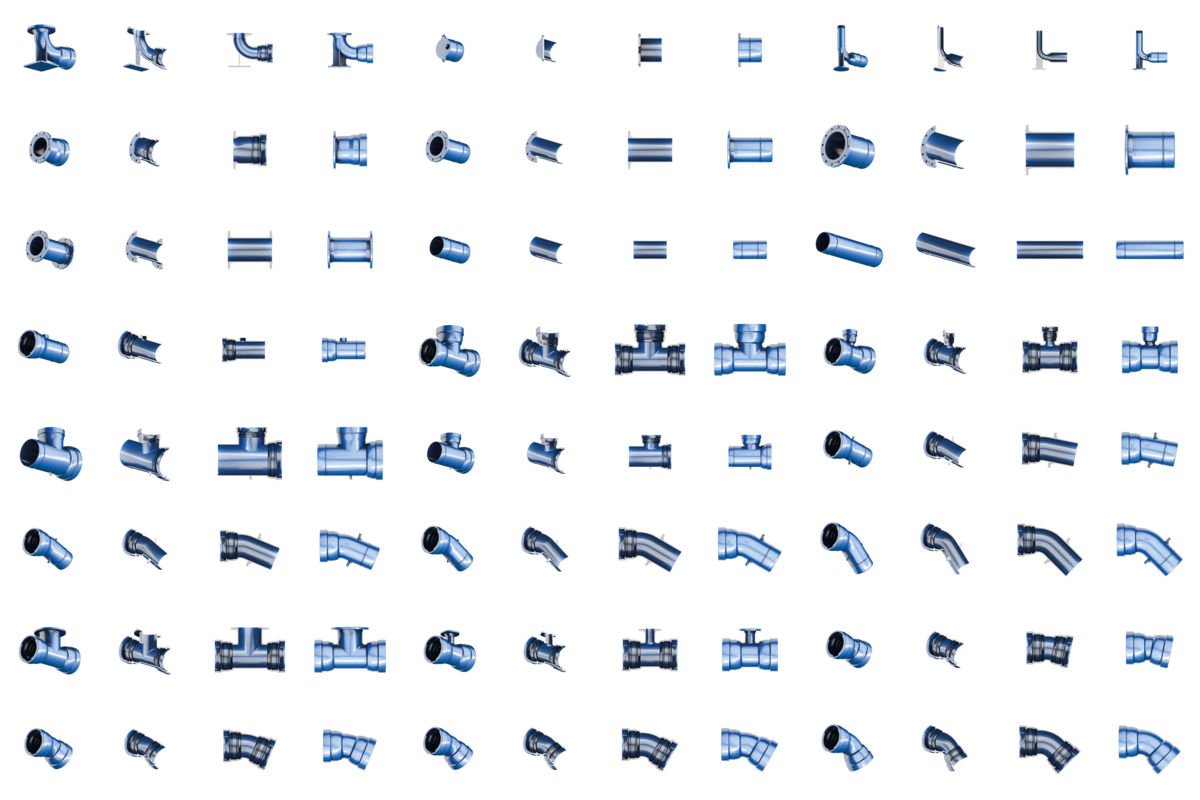

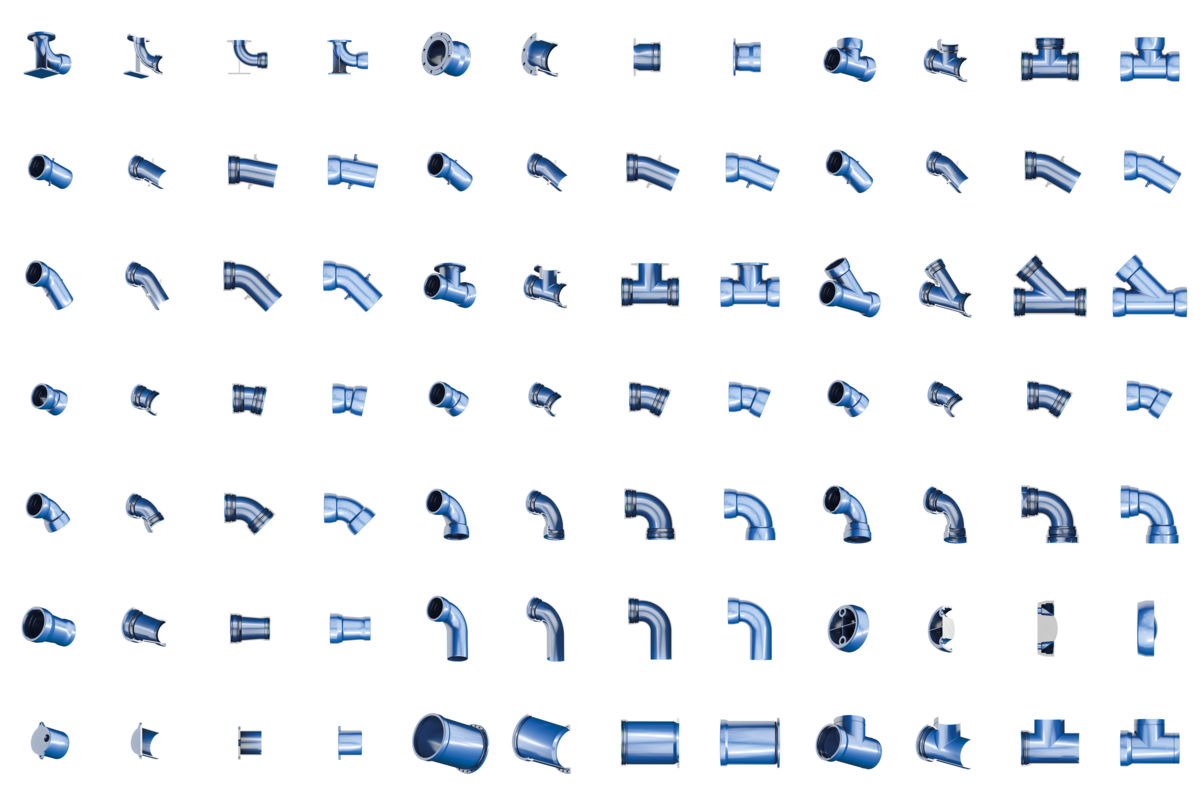

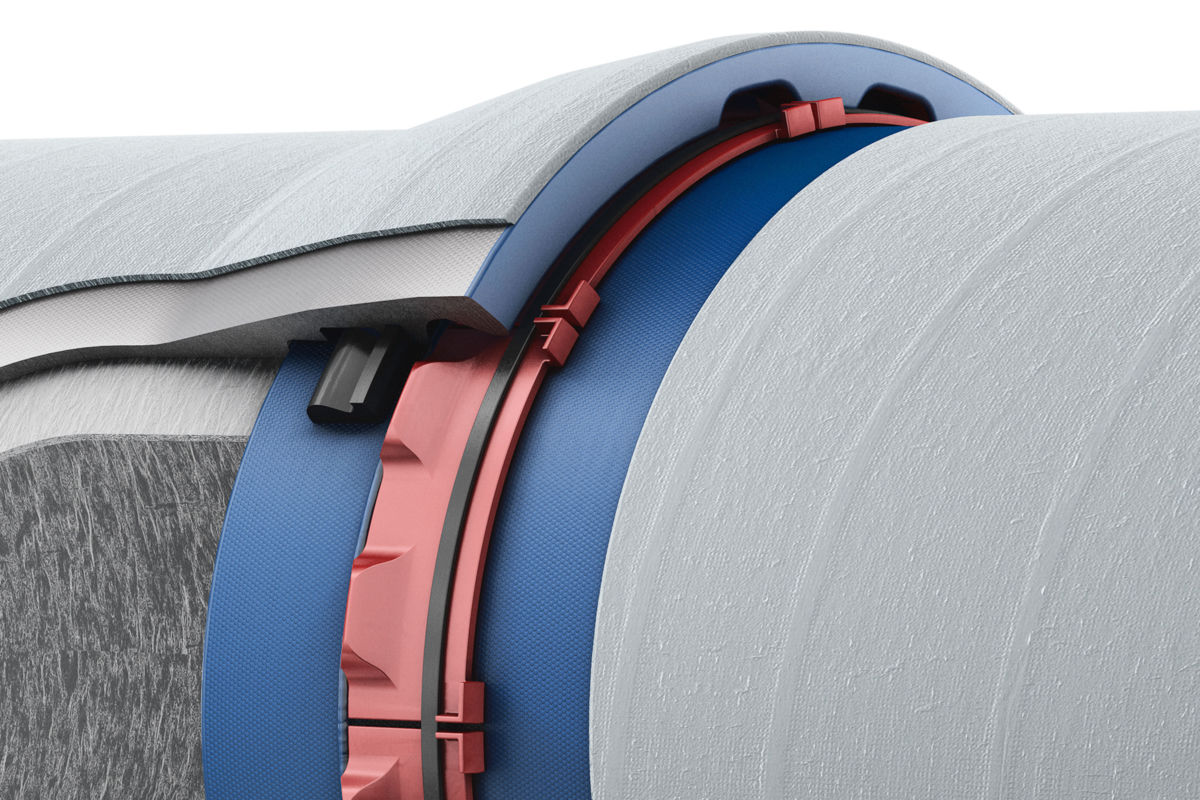

Originally, it was planned to photograph the products. However, with dimensions beyond the 5m and several hundred kilograms of product weight, the limits of available studio space were exceeded. In addition, the preparation, transport, availability and implementation would have caused great effort.

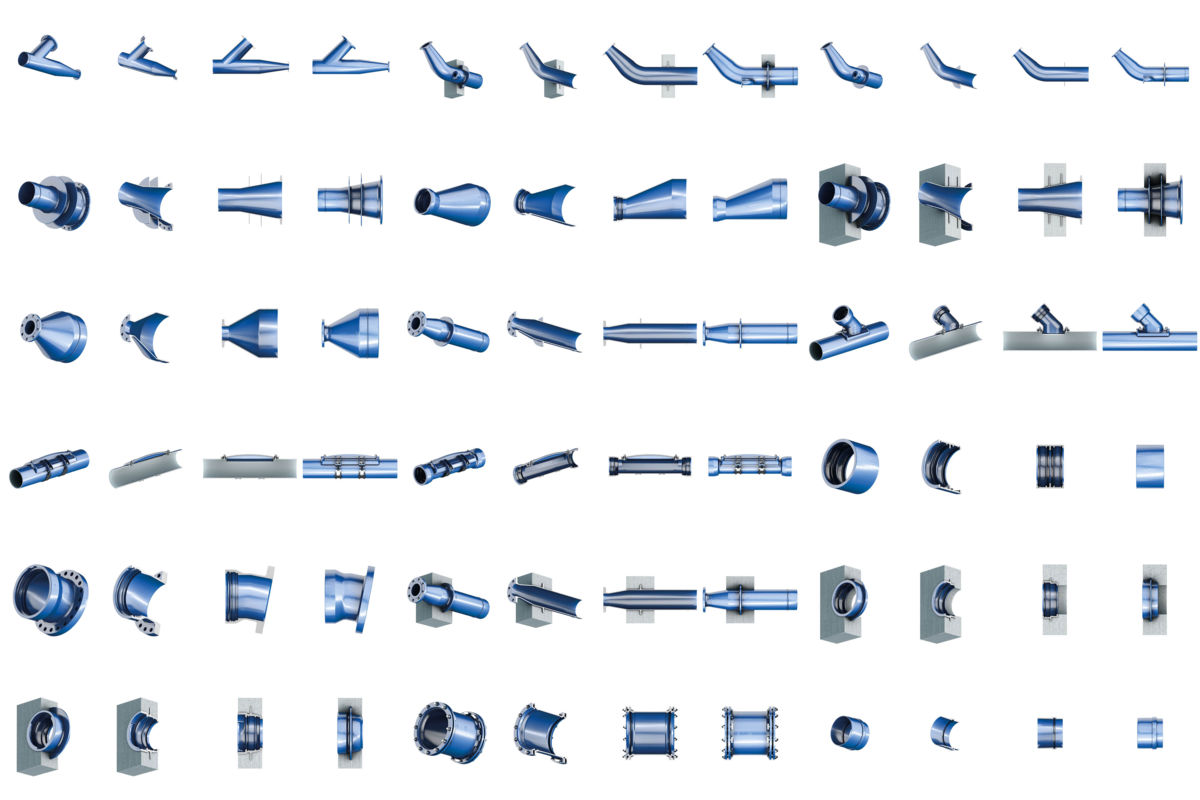

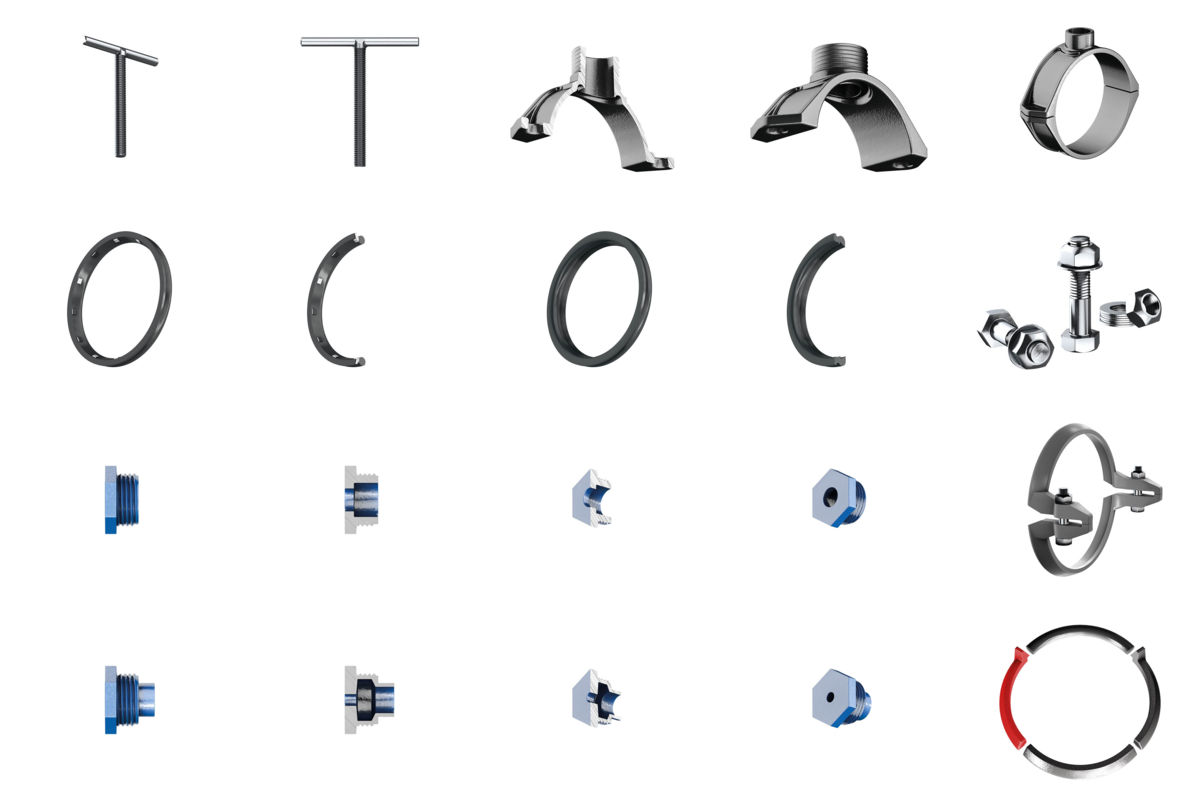

Our proposal to create the product imagery with CGI was gladly accepted. From drawings of the development and construction department, we elaborated a set of detailed 3D models on all available product variations. With this basis we created photorealistic product representations with procedural textures without resolution limit. Thanks to the conscientious work on the models, virtual studios and the lighting, we were able to give the high-quality products a big appearance.

Pile Sujet Sustainability

A composing from multiple images and rendered products.

Cover visual

There was no fitting image available, so we rendered and composed one.

Watchface

We designed a watchface background.

Tiroler Rohre corporate design / corporate identity

Short videoclip for the pitch.

Exhibition Backdrop for piledriver

Background for a exhibition. A real piledriver part for excavators was displayed in front.

How to cut a pile

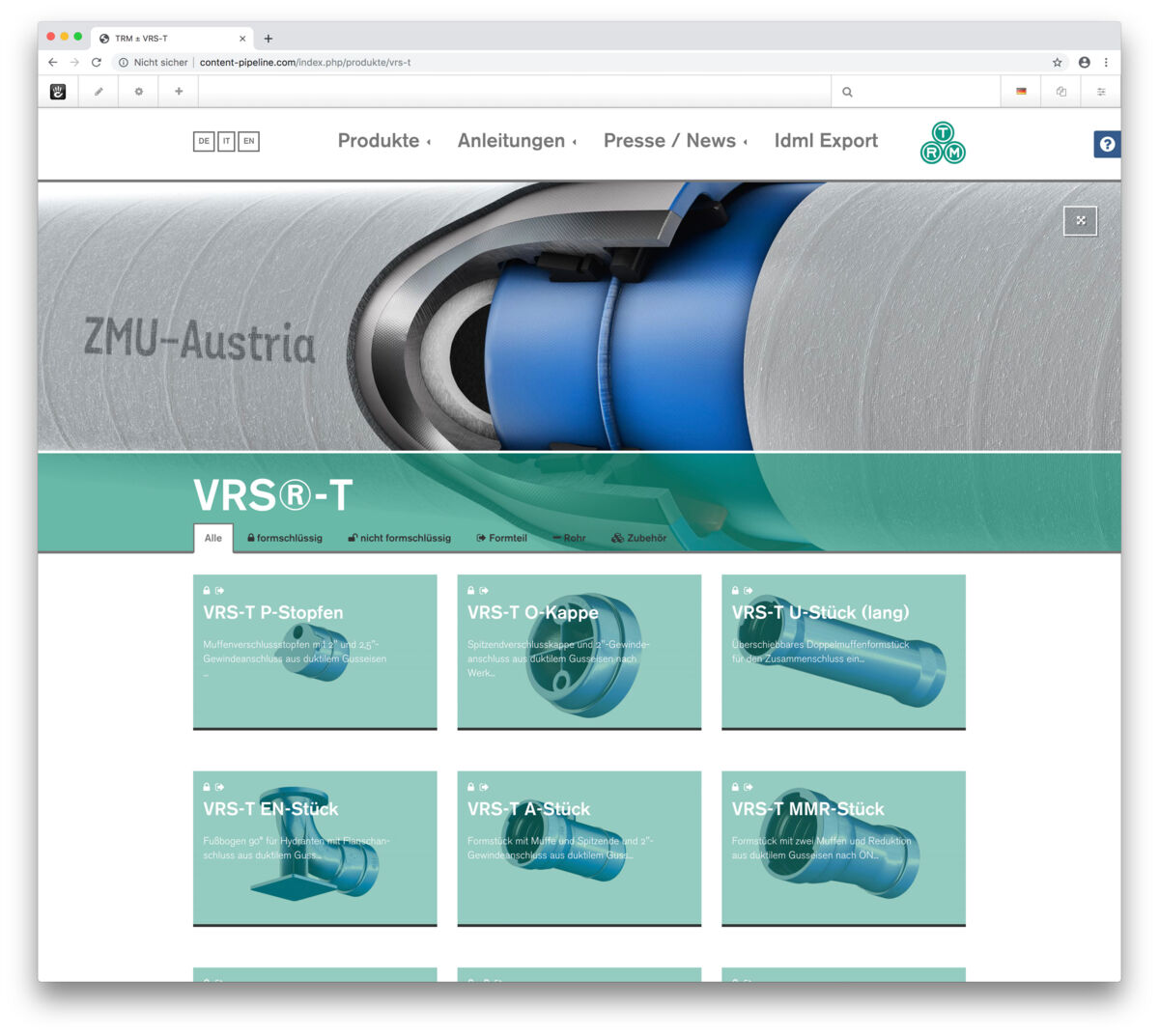

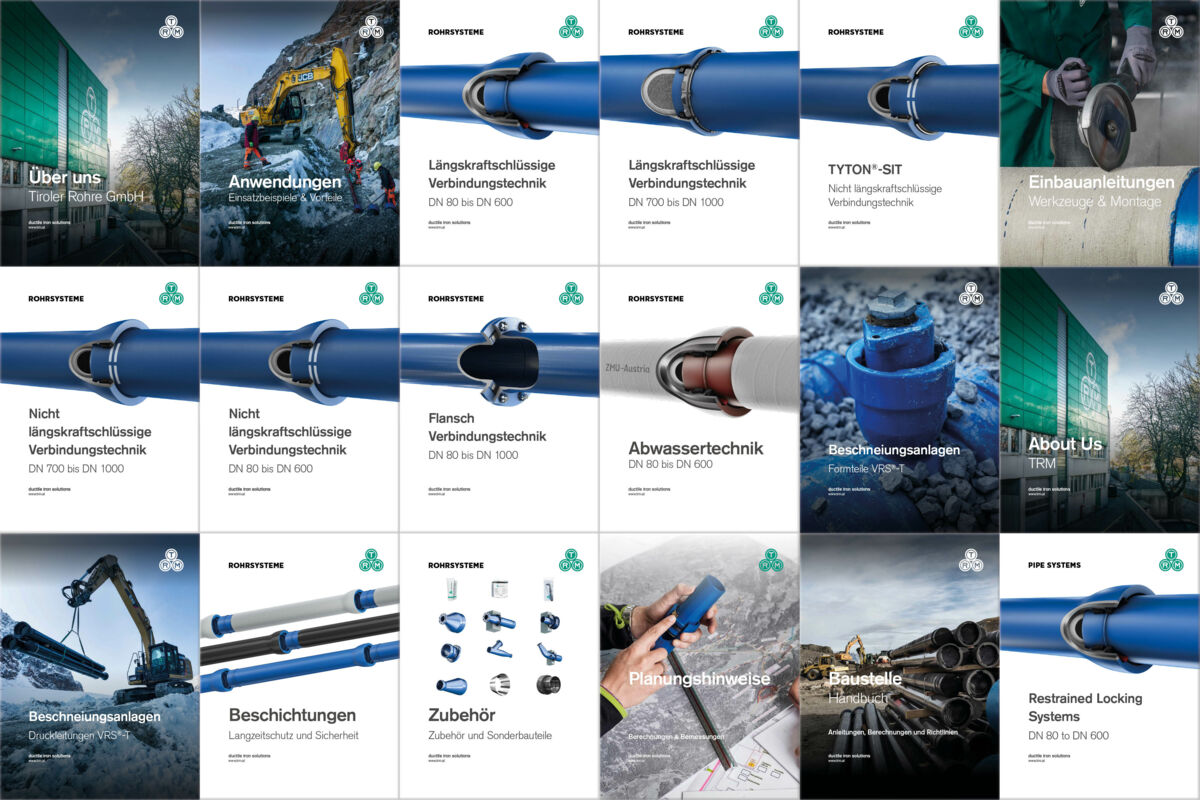

Clear Overviews for Products and Content Pages

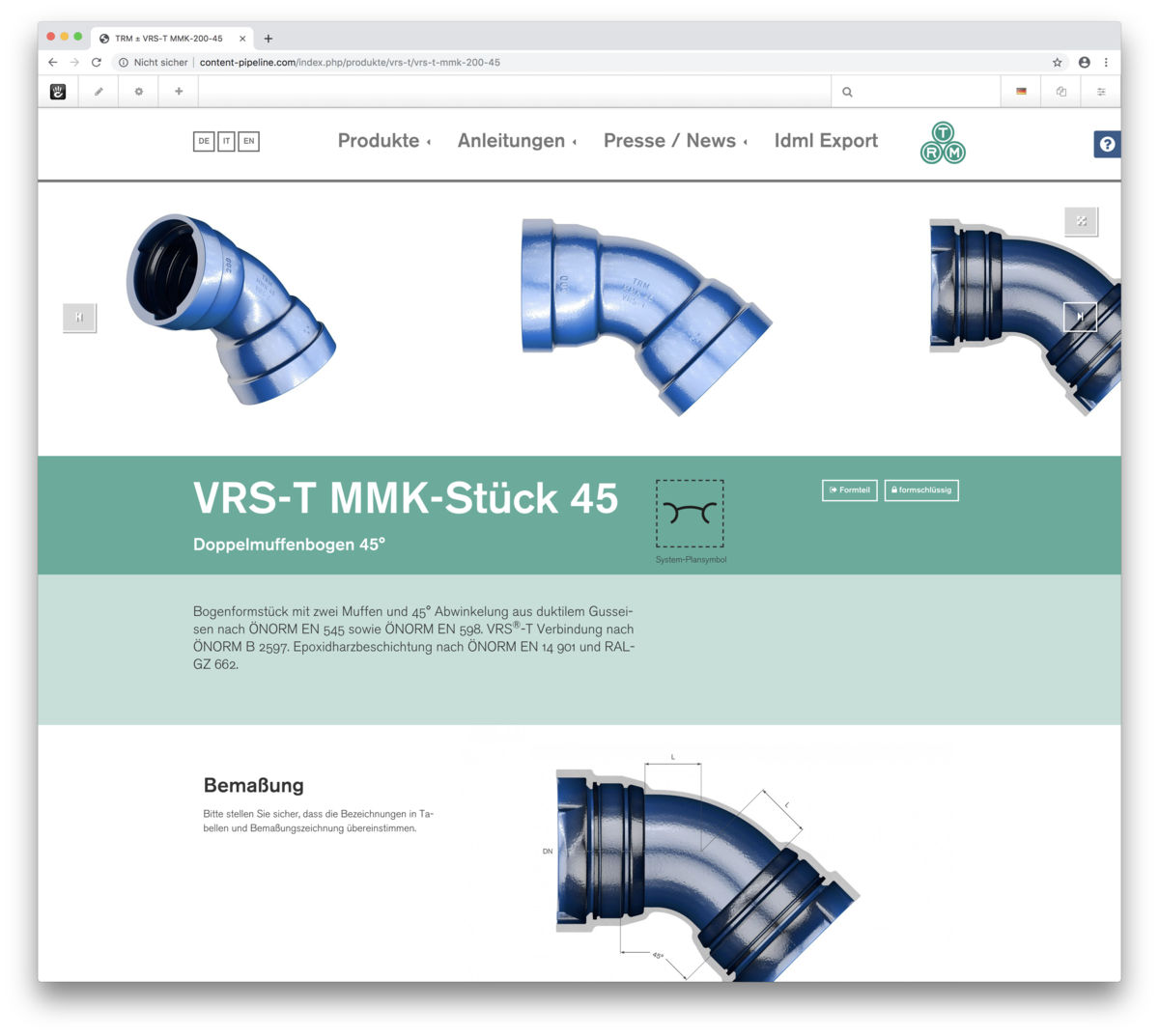

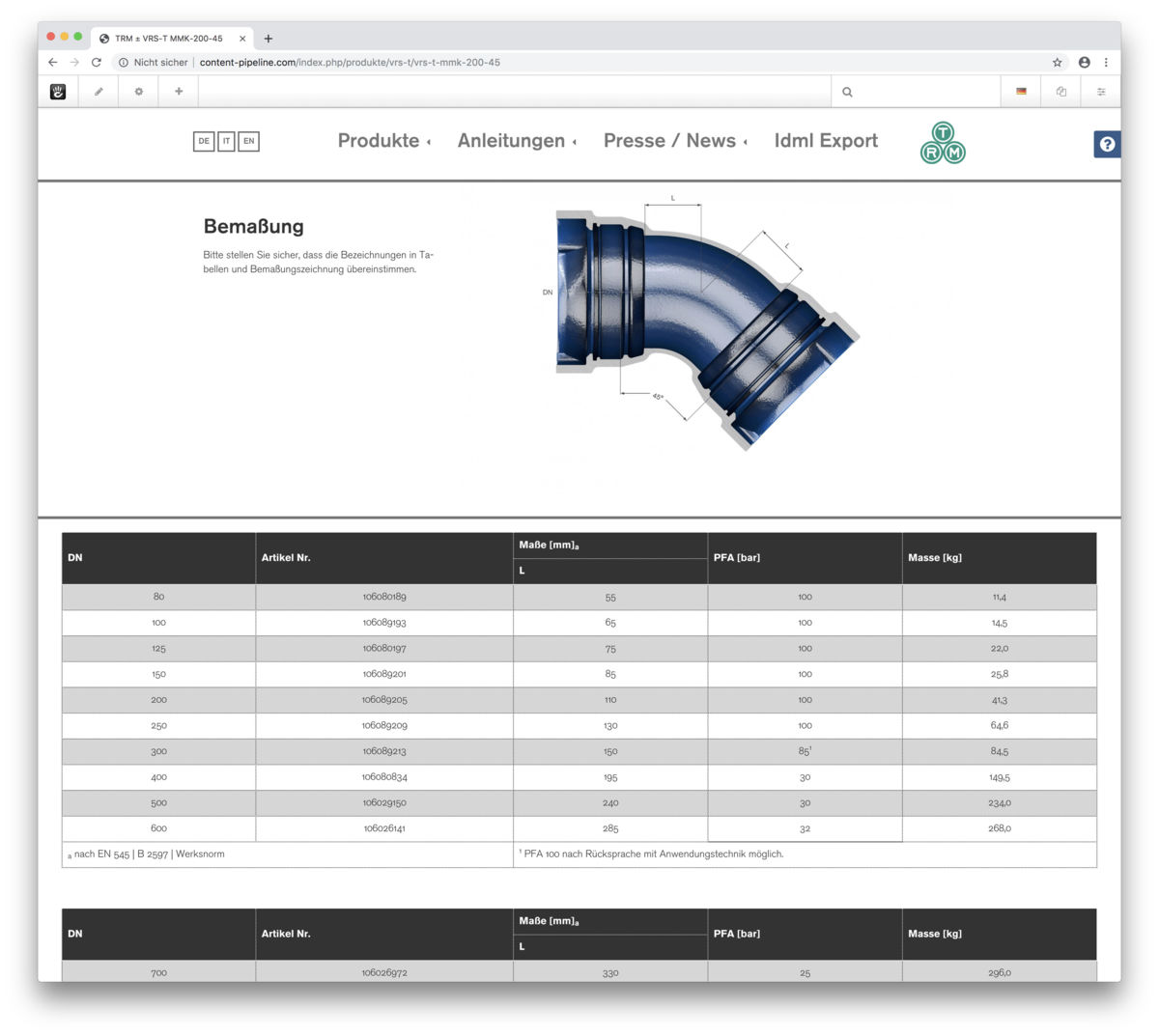

Detailed Product Pages with images, icons, drawings, tables with automatic footnotes, standards and notes

Detailed Product Pages with images, icons, drawings, tables with automatic footnotes, standards and notes

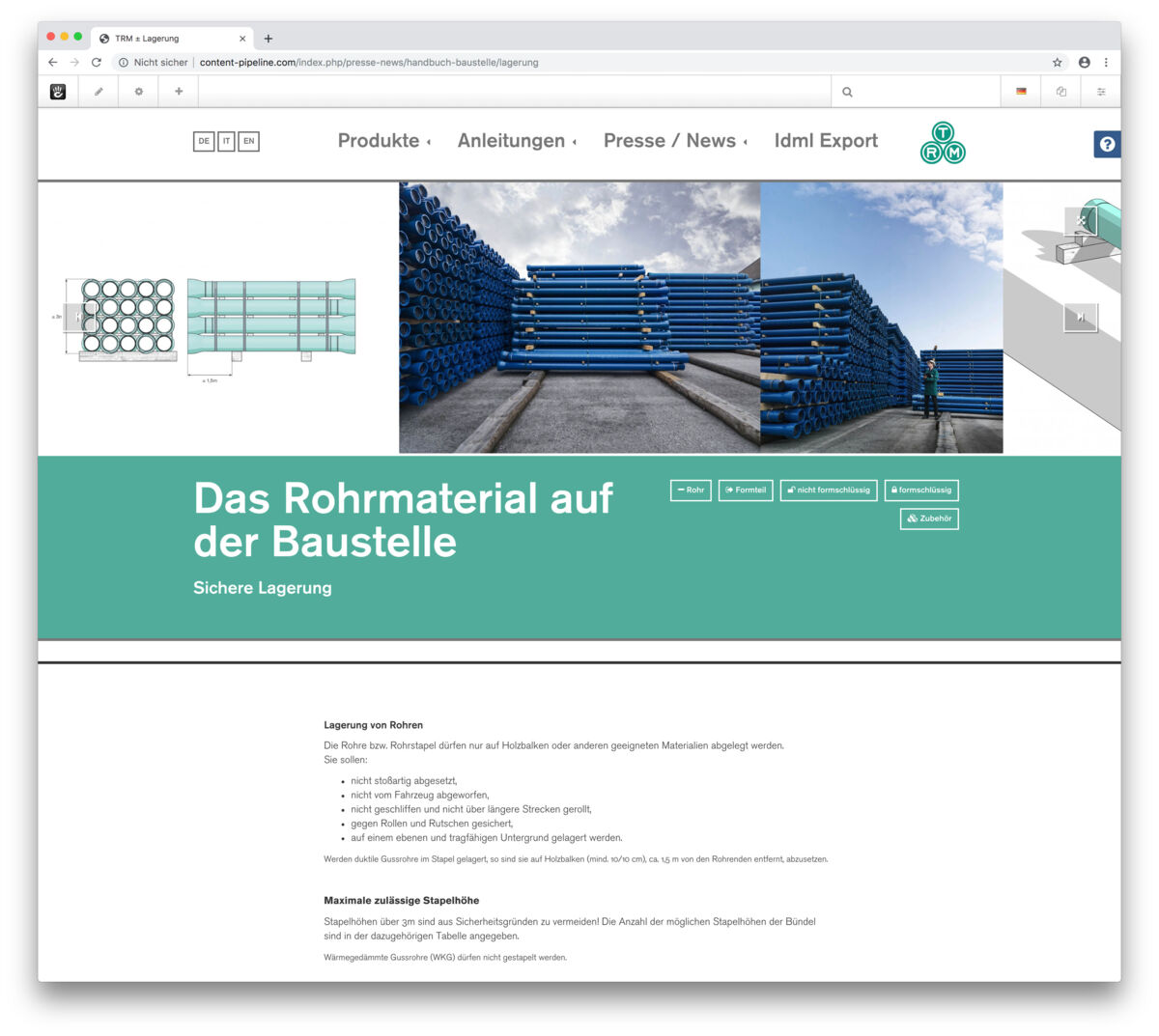

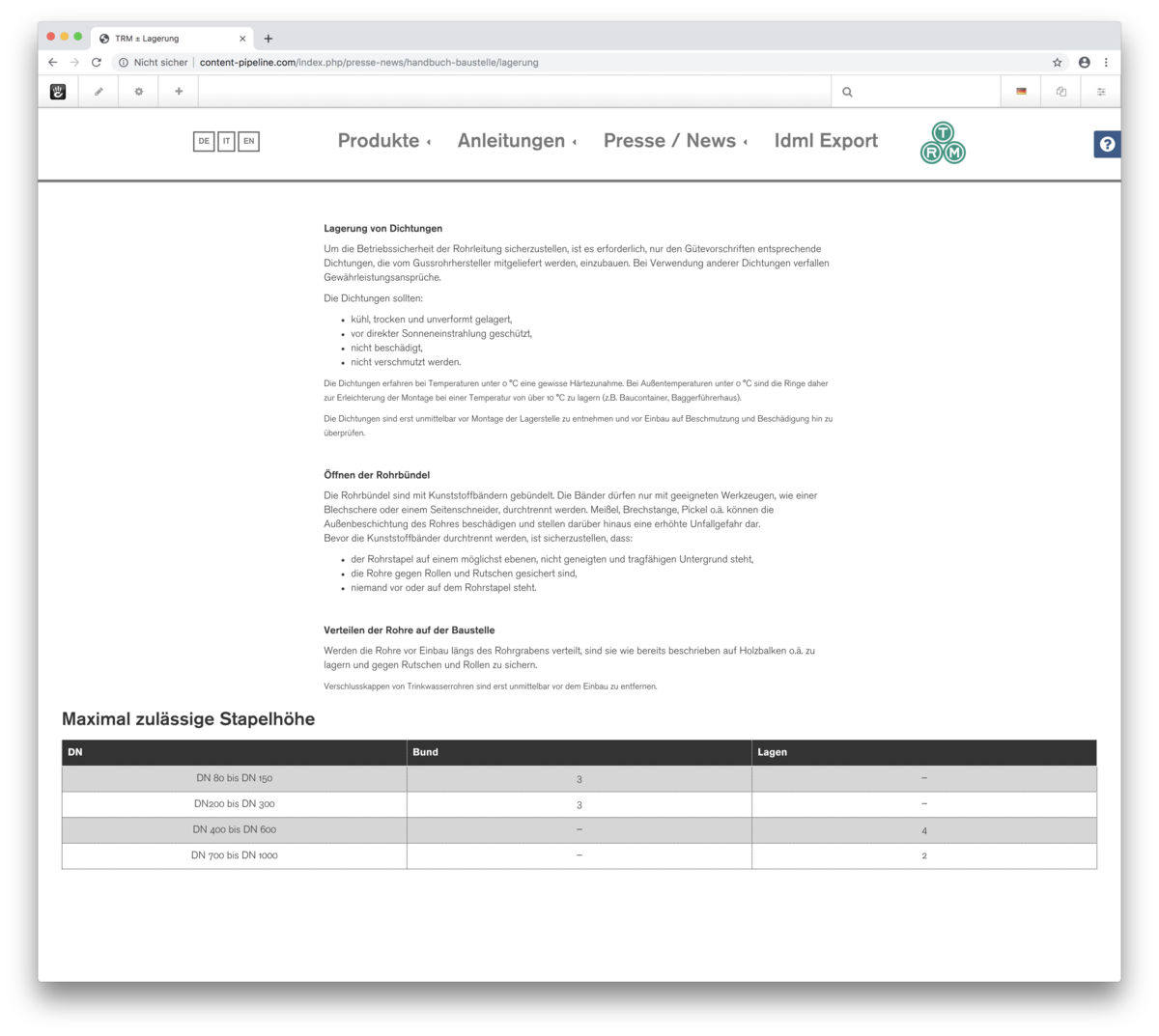

Rich content pages with Images, text, lists, tables, formulas, image descriptions, notes and standards

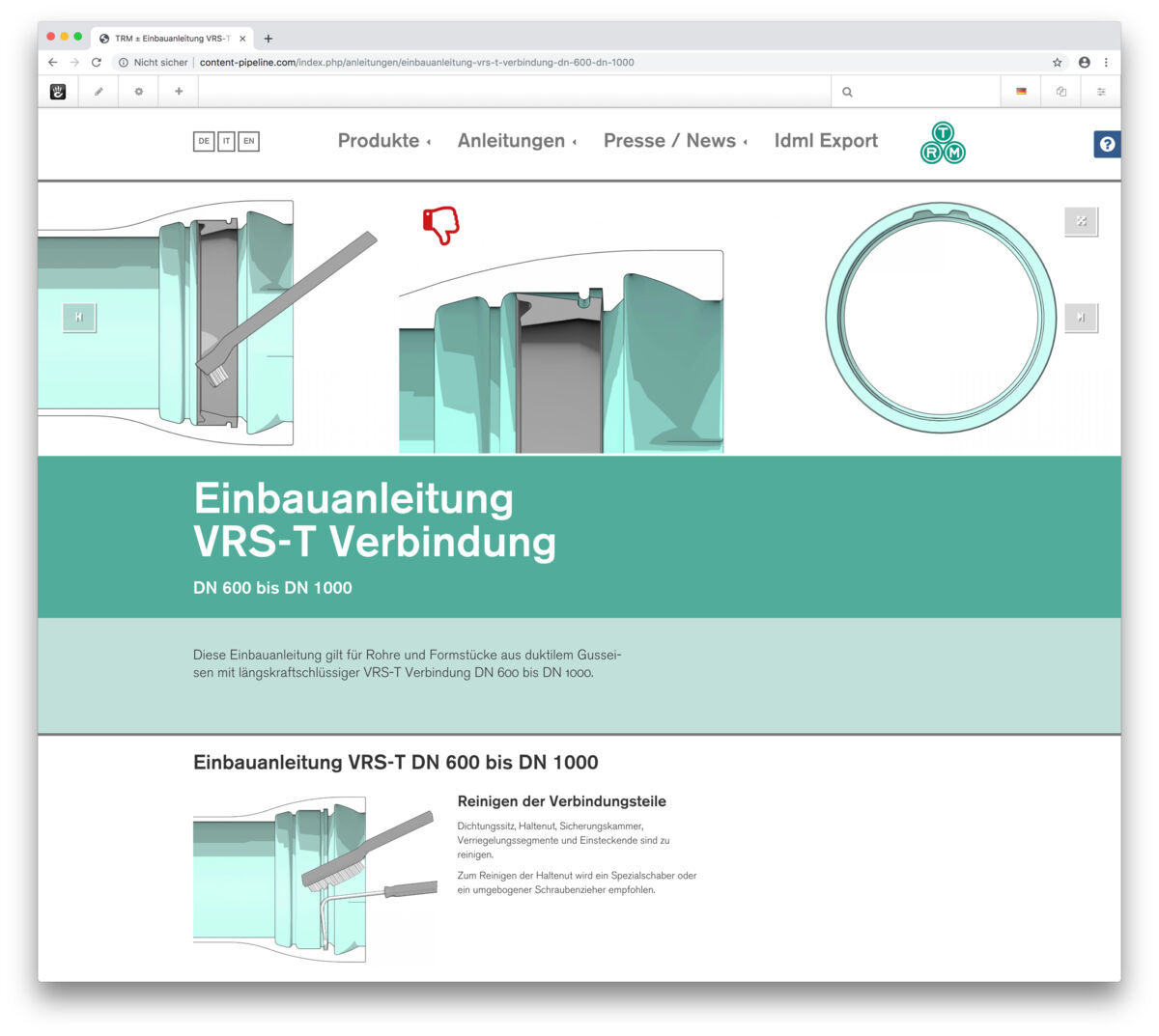

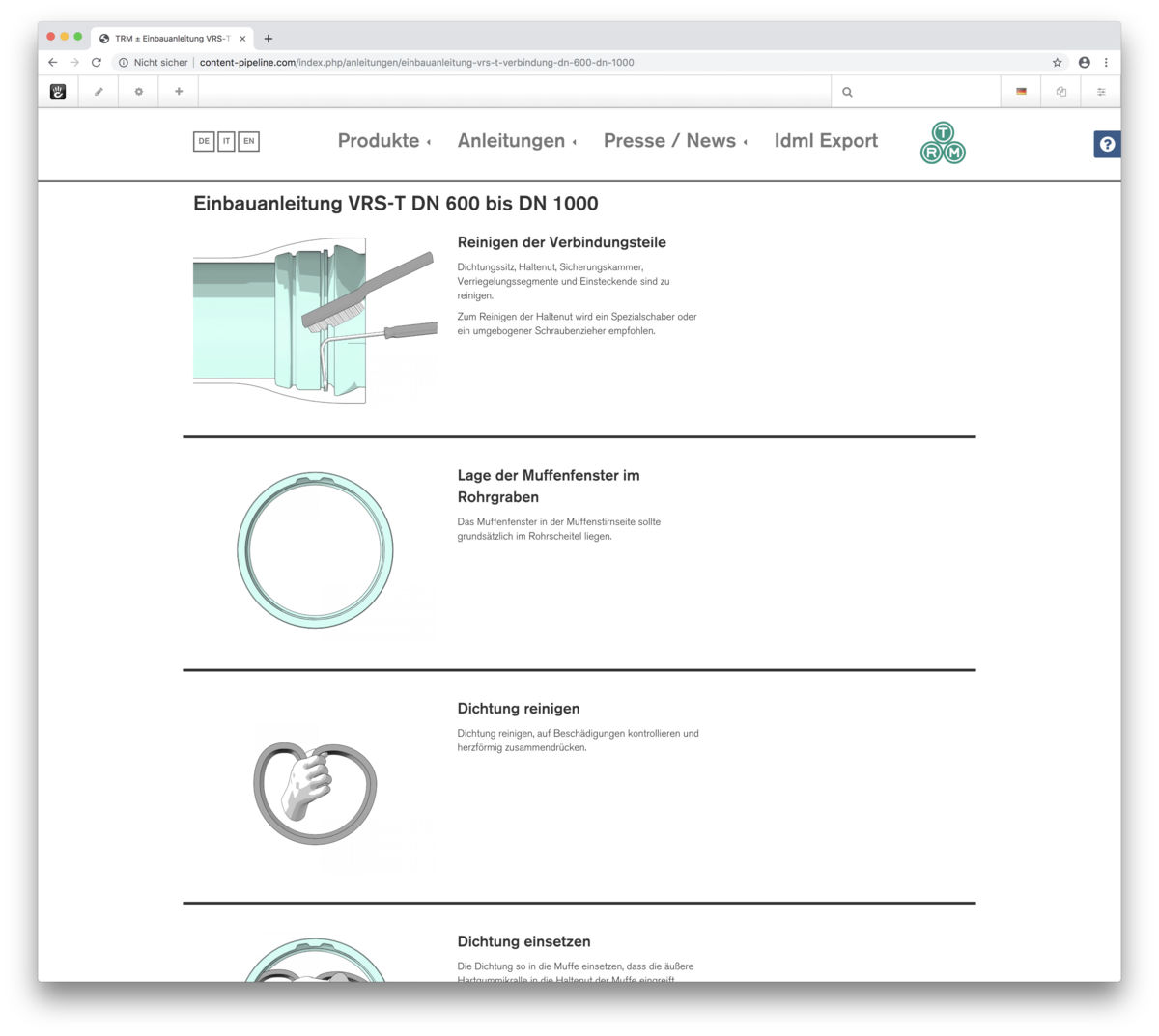

Step-by-step tutorials with reusable steps, notes and captions

Step-by-step tutorials with reusable steps, notes and captions

Adobe Indesign® IDML export with full control over design and formatting

Content Pipeline

The programming of a central marketing content management allows the seamless collaboration between different departments of the customer, the agency, photographers, illustrators, graphic designers and translators. Thus, an always up-to-date and versioned content source could be built with clear and granular text and image components.

Different types of content creation, such as classic CMS editing, automated imports of translated data and bulk creation from database exports, Excel and CSV data complement each other. Always versioned and clearly, every change is subject to a release cycle in which marketing and agency can individually bless or reject the changes made by graphic designers, copywriters and translators.

Often recurring content parts, such as captions, references, standards and guidance steps, are only available once as unique data objects with their translations. Likewise all the images used and of course product and content pages, which are used in different contexts and later brochures.

In this way, we ensure that the content-related error sources, the entire text quantity and thus all translation efforts remain as low as possible via an extensive and detailed amount of content. This also applies to record, print and layout errors due to ongoing release cycles without having to make changes to existing layout and print data each time.

After all contents of a section have received their content release, an export in prepared master layouts is possible. These layouts are to be created for graphic artists as usual, and with simple steps, Adobe InDesign ® designs become exportable IDML master layouts. Due to the fact that the central content is now facing a single central layout file, with all the necessary templates, object, typography and table formats, changes to the design are to be implemented quickly and easily-with the guarantee that later all types of printing will take over these changes correctly.

80 different folders and brochures were exported

No sacrifice in design variety and freedom due to automated production

Clean formatting for technical and mathematical content

Komplex flexible layouts with tables, notes, image captions and recurring content

Step-by-step tutorials with reusable steps, notes and captions

Catalog production

With the help of the content pipeline a precursor of the now online service Content-Crank.com, we were able to let the 80 print types with 12-80 pages in three languages flow automatically into the prepared master layouts within a few days after the respective content releases in the content pipeline platform. In this way, we were able to avoid enormous expenses and delays and print them on a train almost without any typesetting errors. In the case of conventional production, this production would not have been possible, would have caused much higher printing costs and, as a result, typesetting errors and misprints would inevitably have happened.

The conclusion:

- On the customer side approx. 4-6 months of content creation, reviews and approvals with 2 persons

- Catalogues, price lists, product data sheets, instructions, technical information, package leaflets, etc.

- ca. 80 different types of printing/advertising brochures from 12-80 pages

- 54 Module catalogues with 20-80 pages Catalogue production

- total approx. 150 exports in print quality layout variants etc.

- Thousands of tests for possible content types and data structures

- 1500 CMS pages

- 2300 printed pages with partly elaborate pre-press

- 9 days set and production for the trilingual catalogue

- 1 Person

- 0 typesetting errors *

* Of course there are errors-but very few for this content quantity. All errors have been released in multiple instances and can be traced back. The print data export/record did not cause any errors.

Ductile iron pipes with various coatings

Ductile iron pipes with various coatings

Special fittings

Restraint locking fittings

Special fittings

Special fittings

Restraint locking fittings

Restraint locking fittings

Non-restrained locking fittings

Special fittings

Flange joint fittings

Various accessoires

Product images

So far, all product representations of Tiroler Rohre GmbH have been implemented as schematic drawings. In the course of the redesign, we created photorealistic renderings on the basis of the existing in-house construction data. This way, quality and sophistication are palpable in the production process.

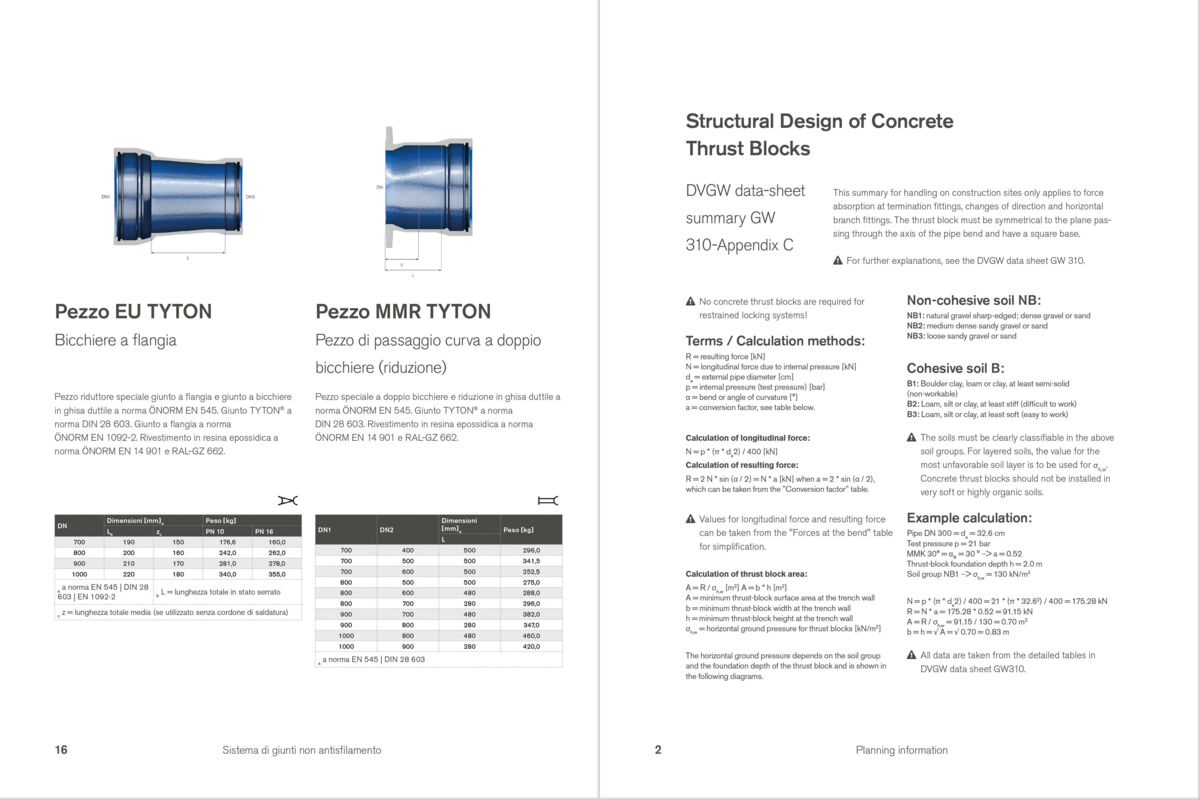

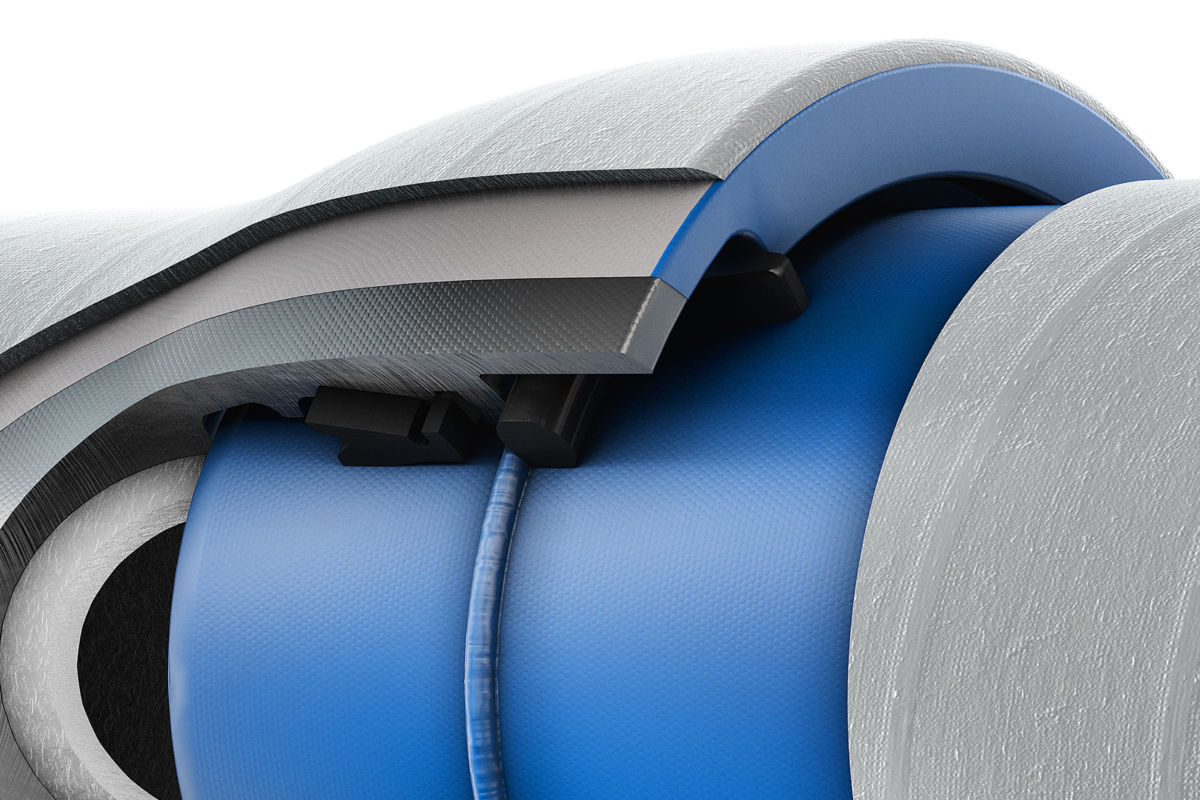

Restrained VRS-T connection

Restrained VRS-T connection

Restrained VRS-T connection

Restrained VRS-T connection

Non restrained TYTON connection

Non restrained TYTON connection

Restrained BRS Connection

Restrained BRS Connection

Sujets pipe connections

Complex technology made tangible. Ductile cast pipe systems of the manufacturer Tiroler tubes GmbH are characterized by a special form-fit and thus load-bearing capacity. This key feature is achieved through a variety of sophisticated connection systems.